Infrared Thermography

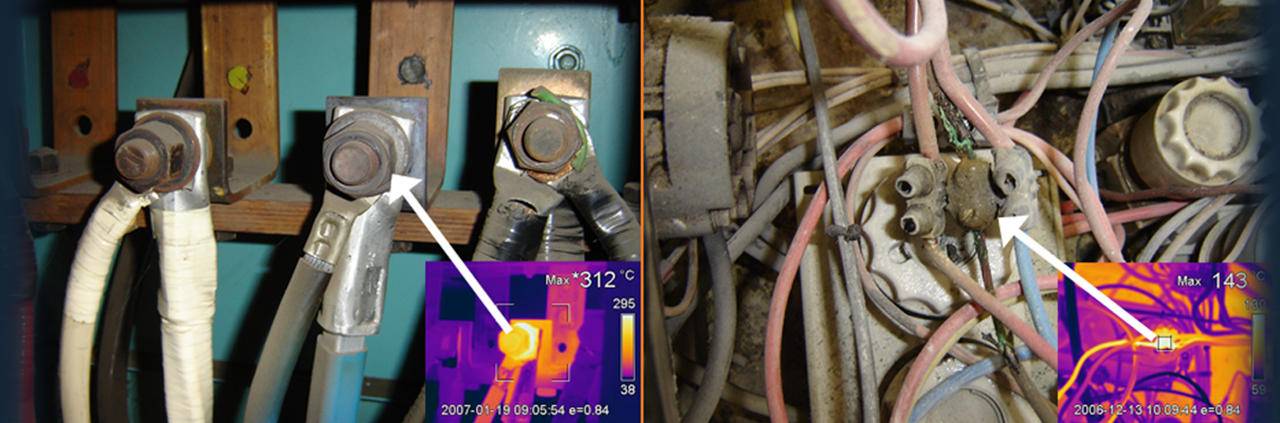

Is the science of acquisition and analysis of thermal information from non-contact thermal imaging devices.

The technology is used for condition monitoring and/or preventative maintenance to optimise maintenance and keep production running smoothly and safely at the lowest possible cost.

An infrared camera is used to pick up "hot spots" in panels, distribution boards and substations. After completion of an inspection, a report is produced and submitted to the client.

Key benefits:

- Predictive maintenance

- Prevent/minimize downtime

- Increase up-time

- Cost-saving solutions

- Prevent or minimise equipment failure

- Increase safety

- Prioritise maintenance scheduling

Applications

Electrical applications include inspecting the integrity of connections and finding hotspots in: | Mechanical applications include the discovery and analysis of faults found in: |

|

|

Using this site means you accept its terms | Copyright © 2025 Thermascan 2020, Port Elizabeth, South Africa. | website by